Key Nominal Dimension b×h | Dimension of Key Groove | Dimension of Key Groove | Reference | ||||||||||||

b | h | h1 | c | ℓ(1) | b1 and b2 | r1 and r2 | Reference Dimension of t1 | Reference Dimension of t2 | ReferenceDimensionoft2,t1 | ApplicableShaftDia.(2)d | |||||

Reference Dimension | Tolerance (h9) | Reference Dimension | Tolerance | Reference Dimension | Tolerance (D10) | ||||||||||

2×2 | 2 | 0 | 2 | 0 | − | 6~30 | 2 | 0.06 | 1.2 | 0.5 | 0.05 | 6~8 | |||

3×3 | 3 | − 0.025 | 3 | − 0.025 | − | 0.16 ~0.25 | 6~36 | 3 | 0.02 | 0.08 ~0.16 | 1.8 | 0.9 | 0 | 8~10 | |

4×4 | 4 | 4 | h9 | 7 | 8~45 | 4 | 2.5 | 1.2 | 10~12 | ||||||

5×5 | 5 | 0 − 0.030 | 5 | 0 − 0.030 | 8 | 10~56 | 5 | 0.108 | 3 | 1.7 | 0.1 | 12~17 | |||

6×6 | 6 | 6 | 10 | 0.25 | 14~70 | 6 | 0.16 | 3.5 | 2.2 | 0 | 17~22 | ||||

(7×7) | 7 | 7.2 | 0 − 0.036 | 10 | ~0.40 | 16~80 | 7 | ~0.25 | 4 | 3 | 20~25 | ||||

8×7 | 8 | 0 − 0.036 | 7 | 11 | 18~90 | 8 | 0.138 | 4 | 2.4 | 22~30 | |||||

10×8 | 10 | 8 | 0 | h11 | 12 | 22~110 | 10 | 5 | 2.4 | 0.2 | 30~38 | ||||

12×8 | 12 | 8 | − 0.090 | 12 | 28~140 | 12 | 5 | 2.4 | 0 | 38~44 | |||||

14×9 | 14 | 9 | 14 | 0.4 | 36~160 | 14 | 0.25 | 5.5 | 2.9 | 44~50 | |||||

(15×10) | 15 | 0 − 0.043 | 10.2 | 0 − 0.070 | h10 | 15 | ~0.60 | 40~180 | 15 | 0.17 | ~0.40 | 5 | 5 | + 0.1 0 | 50~55 |

16×10 | 16 | 10 | 0 − 0.090 | 16 | 45~180 | 16 | 6 | 3.4 | 50~58 | ||||||

18×11 | 18 | 11 | h11 | 18 | 50~200 | 18 | 7 | 3.4 | 0.2 | 58~65 | |||||

20×12 | 20 | 12 | 0 − 0.110 | 20 | 56~220 | 20 | 7.5 | 3.9 | 0 | 65~75 | |||||

22×14 | 22 | 14 | 22 | 63~250 | 22 | 9 | 4.4 | 75~85 | |||||||

(24×16) | 24 | 0 − 0.052 | 16.2 | 0 − 0.070 | h10 | 24 | 0.6 | 70~280 | 24 | 0.214 | 0.4 | 8 | 8 | + 0.1 0 | 80~90 |

25×14 | 25 | 14 | 22 | ~0.80 | 70~280 | 25 | ~0.60 | 9 | 4.4 | 85~95 | |||||

28×16 | 28 | 16 | 0 − 0.110 | h11 | 25 | 80~320 | 28 | 10 | 5.4 | + 0.2 0 | 95~110 | ||||

32×18 | 32 | 18 | 28 | 90~360 | 32 | 11 | 6.4 | 110~130 | |||||||

(35×22) | 35 | 22.3 | 0 − 0.084 | h10 | 32 | 100~400 | 35 | 11 | 11 | + 0.15 0 | 125~140 | ||||

36×20 | 36 | 20 | 0 − 0.130 | h11 | − | 36 | 12 | 7.1 | + 0.3 0 | 130~150 | |||||

(38×24) | 38 | 0 | 24.3 | 0 − 0.084 | h10 | 36 | − | 38 | 0.18 | 12 | 12 | + 0.15 0 | 140~160 | ||

40×22 | 40 | − 0.062 | 22 | 0 − 0.130 | h11 | 36 | 1.00 ~1.20 | − | 40 | 0.08 | 0.70 ~1.00 | 13 | 8.1 | + 0.3 0 | 150~170 |

(42×26) | 42 | 26.3 | 0 − 0.084 | h10 | 40 | − | 42 | 13 | 13 | + 0.15 0 | 160~180 | ||||

45×25 | 45 | 25 | 0 | 40 | − | 45 | 15 | 9.1 | 170~200 | ||||||

50×28 | 50 | 28 | − 0.130 | 45 | − | 50 | 17 | 10.1 | 200~230 | ||||||

56×32 | 56 | 32 | 50 | − | 56 | 20 | 11.1 | 230~260 | |||||||

63×32 | 63 | 0 | 32 | h11 | 50 | 1.60 ~2.00 | − | 63 | 0.22 | 1.20 ~1.60 | 20 | 11.1 | 0.3 | 260~290 | |

70×36 | 70 | − 0.074 | 36 | 0 | 56 | − | 70 | 0.1 | 22 | 13.1 | 0 | 290~330 | |||

80×40 | 80 | 40 | − 0.160 | 63 | − | 80 | 25 | 14.1 | 330~380 | ||||||

90×45 | 90 | 0 | 45 | 70 | 2.50 ~3.00 | − | 90 | 0.26 | 2.00 ~2.50 | 28 | 16.1 | 380~440 | |||

100×50 | 100 | − 0.087 | 50 | 80 | − | 100 | 0.12 | 31 | 18.1 | 440~500 | |||||

Note(1):

From the values for ℓ given below, which are in the appropriate range in the table, one should be selected.

The tolerance for l should be h12 under JIS B0401(dimension tolerance and fitting), in principle.

6,8,10,12,14,16,18,20,22,25,28,32,36,40,45,50,56,63,70,80,90,100,110,125,140,160,180,200,220,250,280,320,360,400

Note(2):

The appropriate shaft diameter should be matched with the torque corresponding to the strength of the key.

Reference:

The nominal sizes given in( )should not be used unless they are absolutely necessary.

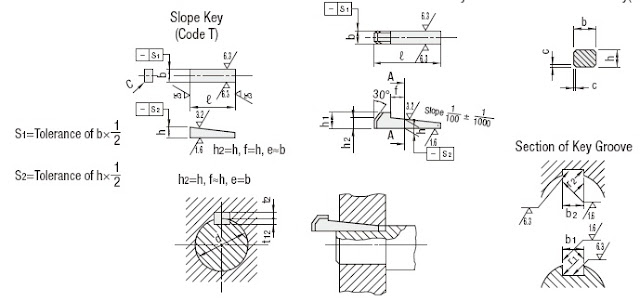

The groove for the boss should be slanted to 1/100, in principle.